CONEFIRE®

Process Firing Burner

The CONEFIRE® series is based on a mixing unit with a central fuel lance and radially symmetrical, staged combustion air supply (mixing cone). The modular design offers extensive options for customizing the burner system. Reliability and low-pollutant combustion have made CONEFIRE® the preferred burner for plate dryers, drying ovens, and afterburner-systems.

CONEFIRE HT®

Description

CONEFIRE HT®

Technical Details

CONEFIRE HT®

Broschure available soon

- Inline burner for thermal oxidiser or air heating (exception)

- Capacity range from 145 – 12.800 kW

- High thermal turn down

- Direct ignition or with pilot burner (up size 5)

- Flame detection with UV-scanner

- Adjustable mixing unit

- Gas -, oil- or combination burner with interchangeable fuel lances

- max. exhaust inlet temperature 600°C

- max. combustion chamber temperature 1.000°C

- Exhaust differential pressure 2 - 8 mbar

- min. O2 content in exhaust 16 vol. %

- Gas turn down up to 1 : 25

- Oil turn down up to 1 : 8

- Exhaust turn down 1 : 2 (with automatic nozzle control to 1 : 8)

- Gas nozzle differential pressure 10-12 mbar

- Oil pressure 6 bar

- Atomizing air pressure 6 bar

CONFIRE GT®

Description

CONFIRE GT®

Technical Details

CONFIRE GT®

Brochure available soon

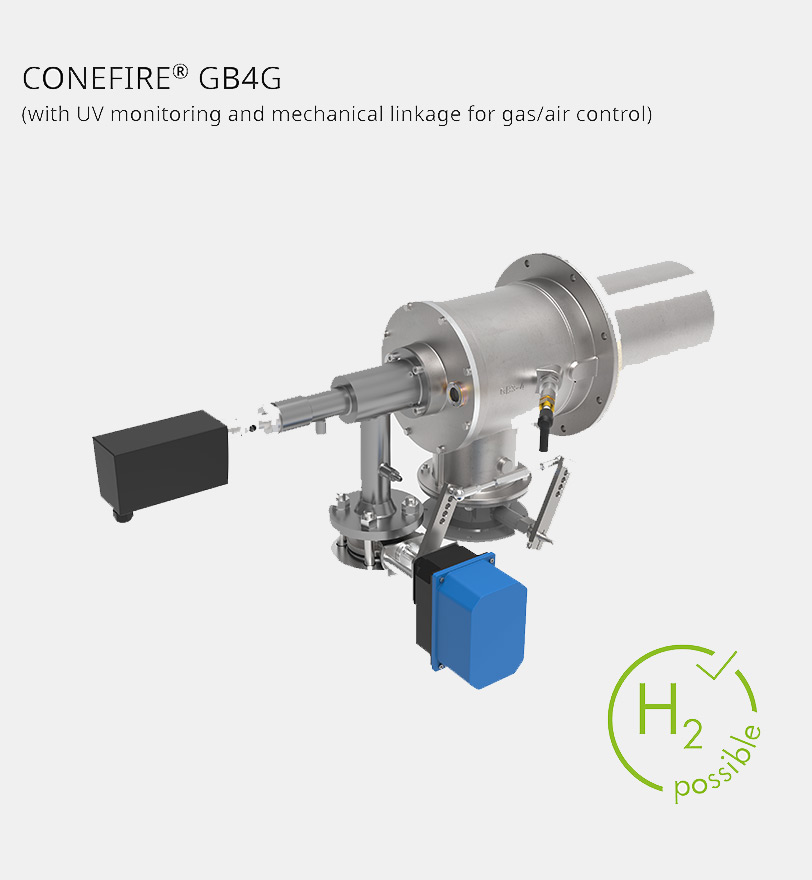

- Gas or multi fuel burner for process heating or drying processes

- Capacity range from 125 – 4.000 kW

- Fuel turn down gas up to 1 : 50

- Fuel turn down oil up to 1 : 10

- Flame monitoring by uv cell, ionization possible

- Low air pressure demand

- Modular design

- Adaptable mixing unit

- Fuel lances for gas, oil, gas oil or other gaseous or liquid fuels available

- With integrated gas pilot by liquid fuel and gas burner > size 4

- Gas nozzle differential pressure 12 – 15 mbar

- Combustion air differential pressure 15 – 20 mbar

- Oil supply pressure 6 bar

- Atomizing air supply pressure 6 bar

- Gas turn down up to 1 : 50

- Oil turn down up to 1 : 10

- Air turn down typical > 1 : 10

- Max. air preheating 200°C

- Max. application temperature 900°C

Contact

Do you have questions about our products or a general concern? Then please contact us via the IBS contact form.

We will process your request as soon as possible and contact you.