Research & Development

We are continually working on innovative solutions to optimise the performance of our industrial burners while simultaneously reducing their emissions. Our aim is to develop modern products in compliance with the highest quality standards that fulfil our customers' requirements and make a positive contribution to environmental protection. At the same time, we demonstrate a high degree of flexibility in customising our products to suit specific customer requirements.

50 % hydrogen always works

With our products, we have many years of experience in the combustion of fuel gases with different compositions, including gases with a hydrogen content of 50 % and more. We are currently working on qualifying our entire product range for 100% hydrogen. Core products as CONEFIRE®, GRIDFIRE®, GBL, RECUFIRE® and LOOPFIRE® have already been successfully tested in the laboratory and partly in field trials for the combustion of pure hydrogen. The combustion of hydrogen-ammonia mixtures is also currently a topic of our research work with very optimistic results. With our development expertise, we see excellent opportunities to bring nitrogen oxide emissions with hydrogen up to the level of natural gas.

Hydrogen capability picks up speed

Most IBS burners have already been successfully tested and approved with a proportion of up to 60% H2 in natural gas. A release of 100% H2 is possible under defined conditions after technical clarification. Performance is limited compared to natural gas operation. We will label these products with H2-possible in future.

We plan to further develop our burners for safe and reliable operation with 100% hydrogen. Innovative solutions should also enable low-emission combustion with hydrogen and provide the usual long service life despite higher thermal loads. We will then label the hydrogen versions of our well-known products with the H2-approved seal.

The resulting new special hydrogen products are also expected to deliver enhanced performance for operation with conventional media such as natural gas. The future has begun, we look forward to the challenges!

Our R&D infrastructure

Our research and development activities take place in a modern test laboratory with a test furnace and multiple test combustion chambers, which are all featured with optical access. Thermal outputs up to 1.5 MW with natural gas are possible. Specific gases can be mixed in any composition. Measurements of burners in direct firing but also in radiant tubes of various designs can be realised. The emission characteristics during air preheating can also be analysed. For conical and air heater burners, it is possible to measure and visually observe them in a test channel under variable process air volumes. Modern flue gas analysis, temperature, pressure and sound measurement are part of our equipment.

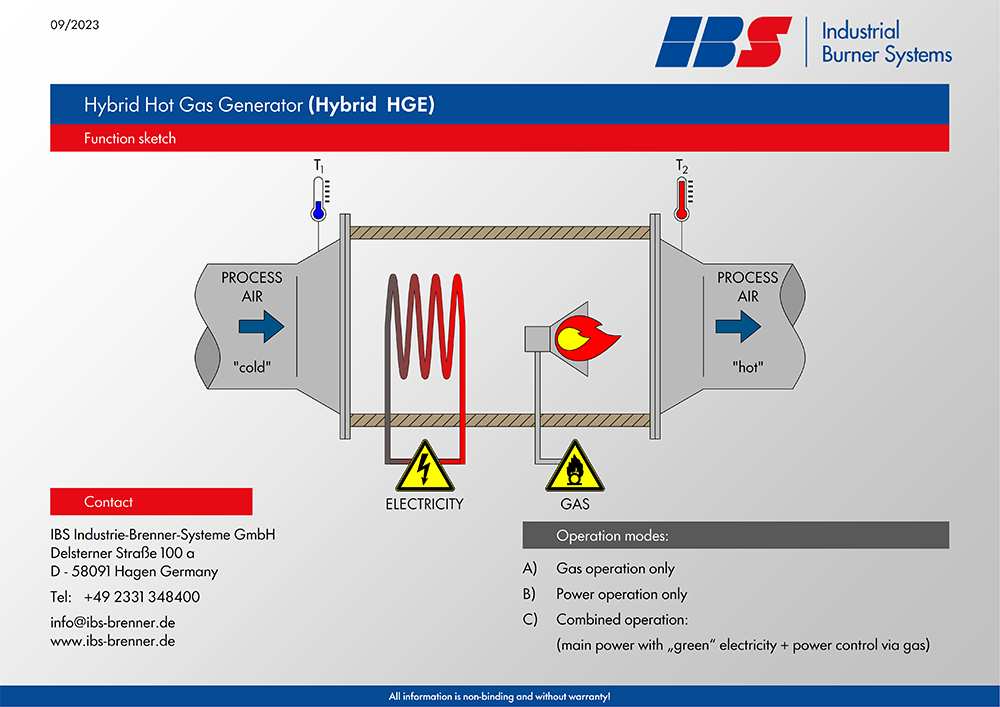

Hybrid hot gas generators

Industrial customers must take decarbonisation efforts or pay CO2 tax. The pressure to save fossil fuels is high. Fossil fuels cannot be substituted easily or at all, so operators must in future focus on an energy mix that will be more climate-neutral overall. Especially customers with high energy requirements have large production halls whose roofs are predestined for photo voltaics. The connection between burner and electric heating is only slightly dependent on each other, so this synthesis (hybrid) is ideal for retrofitting existing gas burners (gas-fired hot gas generators). Existing hot gas generators can be equipped with electric heating coils and the burner can continue operating without significant modifications. Automatically, without interrupting operation, the available, climate-neutral electricity is fed into the system as heat. The temperature is still controlled by the burner. In addition to energy-saving burners and H2 burners, the IBS hybrid hot gas generators are a further contribution to climate neutrality.

Your personal contact

Ernst Keim

Head of development

We are looking forward to your contact!

Contact

Do you have questions about our products or a general concern? Then please contact us via the IBS contact form.

We will process your request as soon as possible and contact you.